The 10-Minute Rule for Baker Marine Contracting

An Unbiased View of Baker Marine Contracting

Table of ContentsGetting The Baker Marine Contracting To WorkThe 25-Second Trick For Baker Marine ContractingEverything about Baker Marine ContractingSome Of Baker Marine ContractingSee This Report about Baker Marine Contracting8 Easy Facts About Baker Marine Contracting Described5 Simple Techniques For Baker Marine ContractingThe Buzz on Baker Marine Contracting

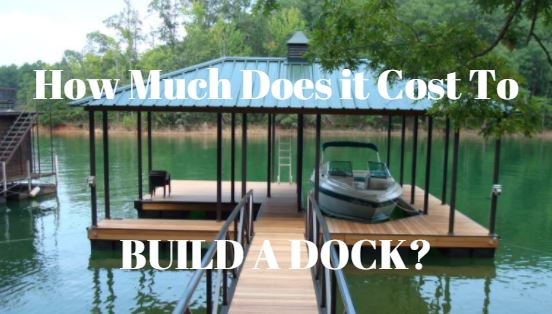

Each kind has its very own building intricacies and product demands, which influence the cost.: Relying on the intricacy of the job, labor can comprise a significant portion of the total cost. Labor prices additionally differ by area and the expertise of the professional. Considering these factors, the price of constructing a watercraft dock can range broadly.

It's essential to think about all these aspects and get a detailed price quote to budget plan appropriately for this waterside investment. Wood docks are often preferred for their natural and timeless visual. Their expenses can vary, largely based on the type of timber picked. While pressure-treated lumber is a more economical choice, hardwoods like cedar or ipe deal remarkable toughness but featured a higher price tag.

Light weight aluminum docks are a prominent choice due to their resilience and reduced upkeep needs. Concrete docks, while the most durable and steady, are additionally the most costly.

Baker Marine Contracting - An Overview

However, they're highly resistant to environmental conditions and can sustain considerable weight, making them a great option for bigger watercrafts. The expense of labor mostly depends upon the size and complexity of the dock. A basic, little dock can be a DIY project for some, but larger, much more complex docks frequently require professional aid.

Labor costs can also differ dramatically based upon your place. Urban areas with a high cost of living tend to have greater labor rates. It's valuable to get several quotes from various professionals to guarantee you're getting a fair price. Last but not least, various other setup considerations might affect the cost. These include website availability, water depth, trend changes, and regional permit needs.

Enhancing your dock's performance and comfort with added attributes will additionally contribute to the complete cost. Things such as boat lifts, benches, ladders, and even built-in storage boxes enhance convenience but come at an added cost. Each of these attributes will certainly vary in rate, so they should be intended and budgeted for appropriately.

Not known Details About Baker Marine Contracting

Building a watercraft dock usually sets you back around $15 to $40 per square foot. Offered that numerous docks share comparable widths, rates is frequently based on the dock's size, i.e., just how far the dock extends over the water.

Fascination About Baker Marine Contracting

In several instances, boat docks are constructed really likewise to conventional decks. They have the same weight distribution, along with the very same light beams, joists and decking. There are a couple of distinctions, however, to help make up the positioning of the dock and the fact that a section of it will be immersed.

Bear in mind that water levels can alter and vary over time, so when intending for the elevation of the dock, keep the highest feasible level as your overview. For lakes, this is easy to locate; situate the water overflow and measure its height. Runoffs are normally installed at the optimum elevation of the lake.

5 Simple Techniques For Baker Marine Contracting

While it's feasible to simply sink wooden articles right into the lake, pond, or ocean bed to produce a dock footer, this isn't necessarily the most steady or the lengthiest long-term service. In many cases, utilizing a PVC pipeline loaded with concrete to border the post makes the finest footer. Either a 12-inch or 18-inch PVC pipe can be used to help sustain the dock, with the pipeline expanding a number of inches up out of the water to ensure that any type of exposed timber will be avoided submerging

The articles will finish up being 8 to 10-feet 66's; they can be cut to height once the concrete sets. As soon as the footers and external messages have been established, you can start building the dock specifically the means you would build a deck. Dock renovations. A structure is produced first to the dimensions and shape you determined, after that decking material is applied

5 Simple Techniques For Baker Marine Contracting

For these factors and even more, service providers and homeowners alike have been trending away from standard pressure treated wood dock planking. Compound outdoor decking is usually suggested for docks since of it's supremacy in wetness resistance compared to pressure dealt with timber, nonetheless it also has downsides to take into consideration. Compound decking is primarily composed of plastic which causes it to warm up in the sunlight, making it hard to stroll barefoot on.

Bear in mind that water levels can transform and change with time, so when intending for the elevation of the dock, keep the greatest feasible level as your overview. For lakes, this is very easy to find; find the water runoff and gauge its elevation. Runoffs are generally installed at the optimum elevation of the lake.

Some Known Facts About Baker Marine Contracting.

While it's possible to just sink wood articles right into the lake, pond, or sea bed to create a dock footer, this isn't necessarily the most secure or the longest enduring solution. Using a PVC pipe loaded with concrete to border the message makes the best footer. Either a 12-inch or 18-inch PVC pipe can be utilized to aid support the dock, with the pipe prolonging numerous inches up out of the water to make sure that any subjected timber will certainly be kept from submerging.

For the most part, the articles will certainly wind up being 8 to 10-feet 66's; they can be trimmed to height once the concrete sets. When the footers and external blog posts have actually been set, you can begin constructing the dock exactly the method you would certainly construct a deck. A frame is created first to the measurements and shape you established, after that outdoor decking material is applied.

Like a standard deck, you have a whole lot of selections for the product made use of to cover the dock. Lots of people who have built with pressure treated wood in the past have actually been explore other materials in more recent years due efficiency problems. While stress dealt with timber is often the most cost conservative dock planking option, it is prone to checking, warping linked here and splitting, especially in an environment so exposed to moisture.

Indicators on Baker Marine Contracting You Should Know

For these factors and more, contractors and home owners alike have been trending far from conventional stress treated timber dock planking. Composite outdoor decking is often advised for docks as a result of it's superiority in wetness resistance compared to press dealt with wood, nevertheless it too has disadvantages to consider. Composite outdoor decking is mainly made up of plastic which causes it to warm up in the sunlight, making it difficult to walk barefoot on.